HOW TO MAKE RAISED PANELS WITHOUT EXPENSIVE TOOLS

Raised panels are a fundamental part of cabinets and furniture. If you're into woodworking, you'll eventually need to make them—and when you do, you’ll be bombarded with videos and articles that demonstrate all sorts of methods using tools you probably don’t have. In this article, I’m going to walk you through how to make raised panels quickly, easily, and safely with just a regular straight router bit.

ARE YOU CLEANING YOUR DUST COLLECTOR FILTER WRONG?

One question I see from time to time really perplexes me. Not because people ask it—that makes perfect sense. I actually find it confusing myself. What I don’t understand is why some filters come with internal agitators for cleaning. This just seems like a bad idea.

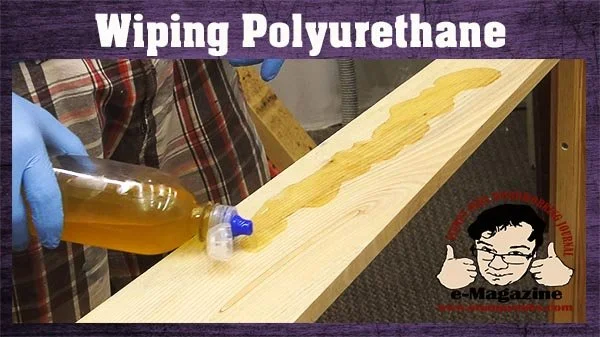

MAKE YOUR OWN WIPE-ON POLYURETHANE

A lot of new woodworkers buy wipe-on polyurethane because it promises to be easy to apply. And that’s true—it is easy to apply. But more experienced woodworkers rarely buy the pre-made stuff. Not because they don’t like wipe-on poly, but because they don’t see the point of paying extra for what is essentially regular polyurethane diluted with inexpensive mineral spirits. You can make it yourself for a lot less money.

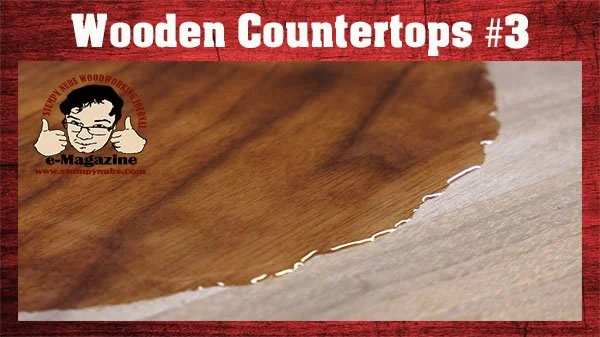

A FINISH DURABLE ENOUGH FOR A WOODEN COUNTERTOP

In this article, I’m tackling one of the most common questions viewers ask: How do you choose and apply a durable finish for wooden countertops?

VENEERING BASICS FOR THE WEEKEND WOODWORKER

Veneering isn’t just for pros—it’s an approachable, game-changing technique that can elevate even small woodworking projects. From contact cement to vacuum pressing, this guide breaks down three practical methods to help you achieve clean, stable, professional-looking panels.

CHECK THIS OUT BEFORE BUYING TURNING TOOLS

Discover the real differences between carbide and traditional woodturning tools, including ease of use, performance, and overall cost. A clear, updated guide to help beginners and hobbyists choose the best turning tools for their goals.

HOW TO SAFELY AGE HINGES AND HARDWARE

Cheap hardware-store hinges can look and function like premium hardware with a few simple fixes and aging techniques. This guide shows how to tighten loose barrels and apply three different patina methods—from natural aging to fast chemical finishes—for a custom, vintage look.

A FASTER METHOD FOR PREPPING AND SHARPENING CARD SCRAPERS

If card scrapers frustrate you, this quick sharpening method will change everything. In just two minutes, you’ll get a perfectly polished edge and a clean, consistent burr that produces real shavings instead of dust.

SEMIGLOSS VS GLOSS VS SATIN

Achieving a consistent satin or semi-gloss wood finish isn’t about the finish itself—it’s all in the flattening agents and how you mix and apply them. Properly stirring, layering, and even polishing satin finishes can give you predictable, beautiful results while maintaining clarity and control over sheen.

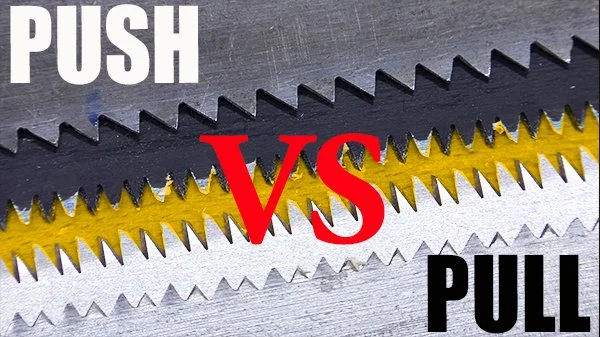

DO JAPANESE SAWS CUT FASTER THAN WESTERN SAWS?

Discover whether Western push saws or Japanese pull saws are faster in the workshop. This detailed comparison explores rip cuts, crosscuts, and joinery to help woodworkers choose the right saw for their style.

HOW PROS MAKE PINE LOOK GOOD WITH STAIN AND DYE

Learn how to prevent blotchy stains on pine and achieve a smooth, professional-looking finish. Discover expert tips using pre-stain conditioners, gel stains, and colored wax for flawless results.

EXTENDING THE LIFE OF GLUE, EPOXY, AND SUPERGLUE

Learn how long common woodworking glues last and how to store them for maximum shelf life. Get tips for PVA, polyurethane, epoxy, CA glue, hide glue, and spray adhesives to ensure strong, reliable joints every time.

BUTT JOINT VS MITER JOINT: WHICH SHOULD YOU USE?

Learn how to choose and execute miter and butt joints for large wood panels like countertops and desktops. Discover tips for handling wood movement, alignment, and fastening to create seamless, durable corner joints.

IS IT BETTER TO SAND, SCRAPE, OR PLANE WOOD?

Sanding, scraping, and planing each have strengths and trade-offs when preparing wood: sanding is the most forgiving and convenient, scraping is slightly faster but physically demanding, and planing is fast and effortless—if the wood cooperates. Choosing the right method depends on your skill level, project needs, and how much you prioritize speed, effort, and control.

DO YOU NEED WOOD GRAIN FILLER BEFORE YOU FINISH?

Grain filler smooths out open-pore woods like oak, ash, and walnut to create a mirror-like surface before finishing, making your projects look more polished and professional. Whether using water-based fillers, pastes, or oil slurries, proper application and multiple coats ensure even pores and better light reflection.

IS SPALTED WOOD DANGEROUS?

Spalted maple is beautifully patterned wood created by fungal activity, prized for its striking black lines and unique coloration, but it can be soft, unstable, and tricky to work with. With careful selection and attention to grain, sanding, and cutting, you can use it to create stunning projects like dovetailed drawers and decorative panels.

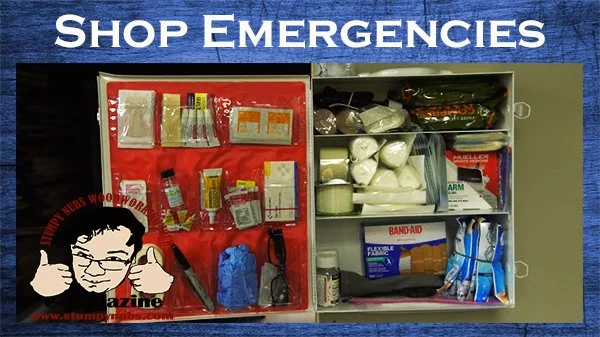

THE FIRST AID KIT WOODWORKERS NEED

Learn how to prepare your woodworking shop for emergencies with a comprehensive first aid kit and practical safety plan. Tips for treating cuts, burns, and severe injuries help keep you and others safe while working with power tools.

HAMMERS AND MALLETS WOODWORKERS NEED TO KNOW ABOUT

Choosing the right hammer or mallet for the task can make woodworking safer, more precise, and more efficient. From cross-peen and ball-peen hammers to dead-blow, lump, and brass mallets, each tool has unique uses that every woodworker should understand.

DON’T THROW THAT UGLY WOOD OUT!

With clever techniques like book-matching, veneering, and using plywood backers, even flawed or sapwood-heavy lumber can be transformed into stunning furniture panels. This article shows practical tips for making the most of every board, creating balanced and eye-catching designs from pieces many woodworkers might discard.

HOW A LITTLE WEDGE MAKES THE STRONGEST JOINT EVER!

The wedged mortise and tenon is one of the strongest mechanical joints in woodworking, combining resistance to shear and tensile forces with a visually striking design. This article walks through every step—from cutting the mortise and shaping the wedges to fitting and gluing the tenon—offering practical tips to avoid common mistakes and achieve a perfect joint.