IS IT BETTER TO SAND, SCRAPE, OR PLANE WOOD?

Sanding, scraping, and planing each have strengths and trade-offs when preparing wood: sanding is the most forgiving and convenient, scraping is slightly faster but physically demanding, and planing is fast and effortless—if the wood cooperates. Choosing the right method depends on your skill level, project needs, and how much you prioritize speed, effort, and control.

DO YOU NEED WOOD GRAIN FILLER BEFORE YOU FINISH?

Grain filler smooths out open-pore woods like oak, ash, and walnut to create a mirror-like surface before finishing, making your projects look more polished and professional. Whether using water-based fillers, pastes, or oil slurries, proper application and multiple coats ensure even pores and better light reflection.

IS SPALTED WOOD DANGEROUS?

Spalted maple is beautifully patterned wood created by fungal activity, prized for its striking black lines and unique coloration, but it can be soft, unstable, and tricky to work with. With careful selection and attention to grain, sanding, and cutting, you can use it to create stunning projects like dovetailed drawers and decorative panels.

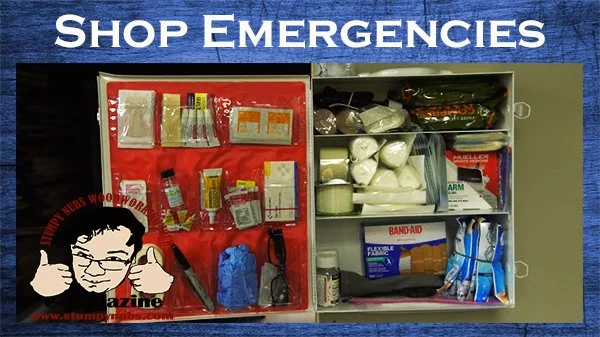

THE FIRST AID KIT WOODWORKERS NEED

Learn how to prepare your woodworking shop for emergencies with a comprehensive first aid kit and practical safety plan. Tips for treating cuts, burns, and severe injuries help keep you and others safe while working with power tools.

HAMMERS AND MALLETS WOODWORKERS NEED TO KNOW ABOUT

Choosing the right hammer or mallet for the task can make woodworking safer, more precise, and more efficient. From cross-peen and ball-peen hammers to dead-blow, lump, and brass mallets, each tool has unique uses that every woodworker should understand.

DON’T THROW THAT UGLY WOOD OUT!

With clever techniques like book-matching, veneering, and using plywood backers, even flawed or sapwood-heavy lumber can be transformed into stunning furniture panels. This article shows practical tips for making the most of every board, creating balanced and eye-catching designs from pieces many woodworkers might discard.

HOW A LITTLE WEDGE MAKES THE STRONGEST JOINT EVER!

The wedged mortise and tenon is one of the strongest mechanical joints in woodworking, combining resistance to shear and tensile forces with a visually striking design. This article walks through every step—from cutting the mortise and shaping the wedges to fitting and gluing the tenon—offering practical tips to avoid common mistakes and achieve a perfect joint.

WHEN A KNIFE IS BETTER THAN A PENCIL

Choosing the right marking tool can make a huge difference in woodworking accuracy and efficiency. This article explains when to use pencils, mechanical pencils, marking knives, and marking gauges, with practical tips for selecting the proper tool for rough layout, precise joinery, and everything in between.

DO YOU NEED A WOOD MARKING GAUGE?

A marking gauge is a timeless woodworking tool that provides precision and repeatability that pencils and rulers alone cannot. This article explores different types of gauges—pin, knife, and disc-style—explaining their uses, proper technique, and applications for joinery, layout, and surface marking.

WHY SHARP ISN’T ALWAYS BEST - DULL CHISELS

While sharp chisels are essential for most woodworking tasks, a deliberately blunt chisel can be a surprisingly useful tool for controlled paring and shaping, especially across the grain or on end grain. This article explains how to create a crisp blunt edge, when to use it, and the advantages it offers over ultra-sharp tools in specific scenarios.

HOW LOCK MITERS CAN MAKE PROJECTS CHEAPER AND BETTER

Learn how to build thick, solid-looking furniture legs from thinner stock using lock-miter joints. This guide covers grain control, safer cutting techniques, and precise assembly for professional-quality results.

LOOSE-TENON JOINERY WITHOUT A FESTOOL DOMINO

Loose tenons simplify traditional mortise and tenon joinery, allowing faster, more repeatable joints without sacrificing strength. This article walks you through creating a custom mortise jig, cutting precise mortises with a router, and sizing loose tenons for a flawless fit.

DO BEVEL ANGLES MATTER?

Some people insist on a precise angle for pine, a different one for oak, another altogether for cherry, one angle for long grain, another for end grain. If you work with a lot of different woods, you'd need a hundred different planes or chisels set up with different bevels, or else you'd be regrinding your tools to nubs with the constant changes.

HOW TO STOP WOOD PANELS FROM WARPING

If there’s one thing that’s popular in the woodworking world these days, it’s a good old-fashioned myth-busting video. Some of them are complete nonsense, of course. But this myth? It’s real: flat panels—such as table tops and cabinet tops—will warp uncontrollably if you don’t cut them into narrow pieces, flip every other board to alternate the grain direction, and then glue them back together.

IS JAPAN SLOWLY KILLING WESTERN-STYLE SAWS?

But there’s still a great deal of confusion about how these saws work, the differences between the types available, and whether a Japanese saw is right for you. Most videos and articles focus on the benefits of these tools while largely ignoring the downsides. In this article, I want to present a clear, concise guide to the pros and cons of the three most common types of Japanese saws, so you can make an informed decision about which to try—if any at all.

THE HISTORY OF WOOD SCREWS

For thousands of years, nails were the only metal fasteners used to attach things together. In a previous article, we discussed how nail technology evolved over time—and why old-fashioned cut nails may actually work better than modern wire nails. In this article, you will learn the fascinating history of screw technology—and why screws aren’t always the best choice.

READ THIS BEFORE USING OIL-BASED POLY FINISHES!

Today, I want to talk about oil-based polyurethane. It’s a very durable finish that’s well-suited for both indoor and some outdoor projects. It’s not difficult to apply, but I think my method will give you the best results.

ROUGH SAWN BOARDS AND THE TABLE SAW

I’ve cut rough boards on the table saw before, and I still have my fingers. I know many of you have gotten away with it, too. Not every rough-sawn board is equally dangerous. There are levels of roughness. A board that’s a little woogedy presents far less risk than one with a big twist in it. So keep things in perspective as we proceed.

HOW TO GROUND YOUR DUST COLLECTION

So in this article, I will teach you how to ground a PVC dust collection system properly, including answering some of the most common questions people have—such as how to address your flex hose, whether to run wire inside or outside the ductwork, and how to get that charge from the pipes and hoses into the physical ground.

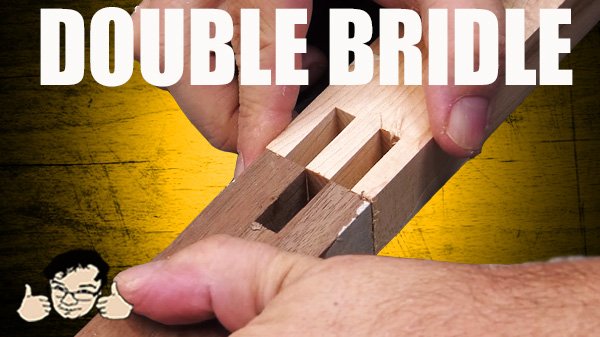

JOINERY LESSONS FROM THE DOUBLE BRIDLE JOINT

The double bridle joint is a great way to practice precise, repeatable joinery on the table saw, and it teaches you how to sneak up on a perfect fit instead of relying solely on pencil lines. With a simple tenon jig and the right blade, you can create a strong, attractive joint that’s customizable and clean.