ROUGH SAWN BOARDS AND THE TABLE SAW

Cutting rough or warped boards on a table saw is risky due to bows, twists, cups, and crooks that can cause kickback or binding. This guide explains the dangers and offers safer alternatives, including band saws, hand planes, jigs, and proper use of splitters or riving knives.

In previous videos, I’ve referred to the table saw as a poor choice—or even a dangerous tool—for cutting rough-milled boards. I’ve explained why, but the question comes up often enough that I think it’s worth having a short, dedicated video (and now blog post) explaining the potential dangers involved. That way, I can point folks here when the topic arises.

Yes, this is a safety post. There are plenty of other tutorials on our channel if you feel confident in your safety knowledge. But I think it’s always good to get an occasional refresher, so I hope you’ll stay with me through this post.

Let me begin by saying: I’ve cut rough boards on the table saw before, and I still have my fingers. I know many of you have gotten away with it, too. Not every rough-sawn board is equally dangerous. There are levels of roughness. A board that’s a little woogedy presents far less risk than one with a big twist in it. So keep things in perspective as we proceed.

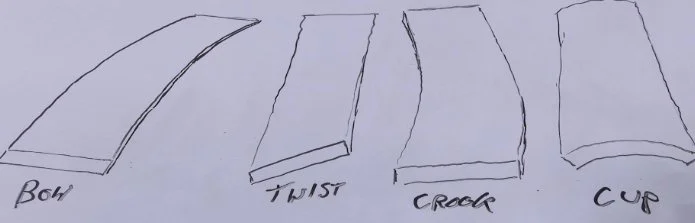

The real problem with rough stock isn’t the rough surface—it’s the distortion that often occurs during the drying process. A board may develop a bow, twist, crook, or cup after it's cut from the tree. That’s what I mean by rough stock: material that hasn’t been properly flattened and straightened with a jointer and planer since drying. Cutting such a board on a table saw can lead to a dangerous kickback that could strike and seriously injure you—or even pull your hand into the blade before you have time to react.

Bowed Boards

Let’s start with a bowed board. This is perhaps the least dangerous scenario, but risks remain if the board doesn’t lay flat on the saw during the cut. With the crowned side down, the board may rock. Flipped over with the hollow side down, the board must wrap over the saw top—falling at the start of the cut, then rising toward the blade. That movement might not affect the cut directly, but when you sacrifice stability, you compromise control—and that’s never a good thing.

Twisted Boards

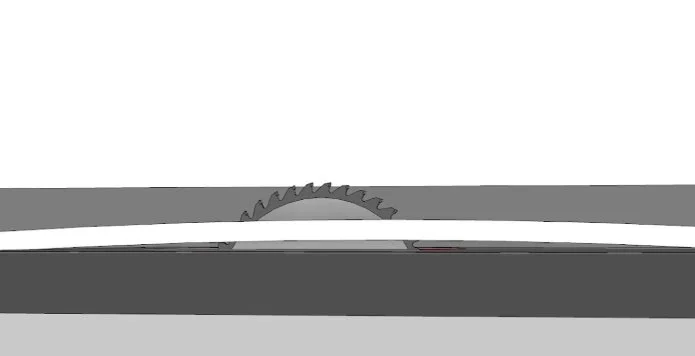

Now, consider a more dangerous scenario. Imagine you’re ripping a board and you twist or rotate it mid-cut. In the below picture, you will see how the cutting path shifts relative to the blade. This puts pressure on the side of the blade, which increases friction and can cause binding—and potentially shoot the board right back at you. If your hand is close to the blade, it may even be pulled in with it.

If you rotated a board mid-cut, it puts pressure on the side of the blade, increasing friction and could cause binding - and potentially kickback.

Of course, none of us would intentionally rotate a board during a cut. But if you’re trying to cut a warped board with a natural twist, it may rotate on its own as it rocks from one position to another. You may think you can hold it steady—but it’s better to decide whether you're using poor judgment before the cut than to say, “Man, that was stupid,” after the cut.

Cupped Boards

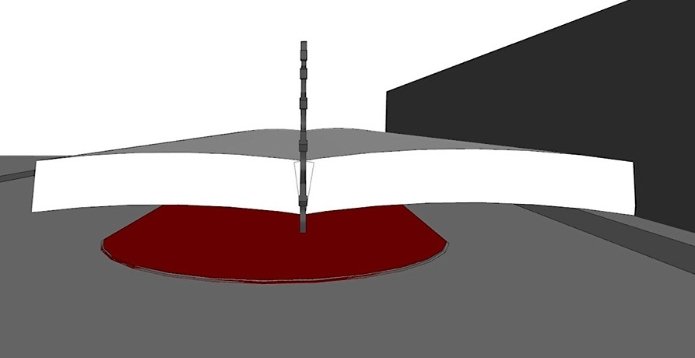

A more common issue involves ripping a cupped board. With the crowned side down, the board may rock, putting pressure on either side of the blade. The more stable orientation is crown-up, so there are two points of contact on the saw top and no rocking.

In the above picture you can see what happens once the board is cut in two—it collapses downward, potentially pinching one or both sides of the blade. That’s a recipe for kickback or binding.

You must have a flat, stable surface on top of the saw to make a safe cut. No bows, no twists, no cups.

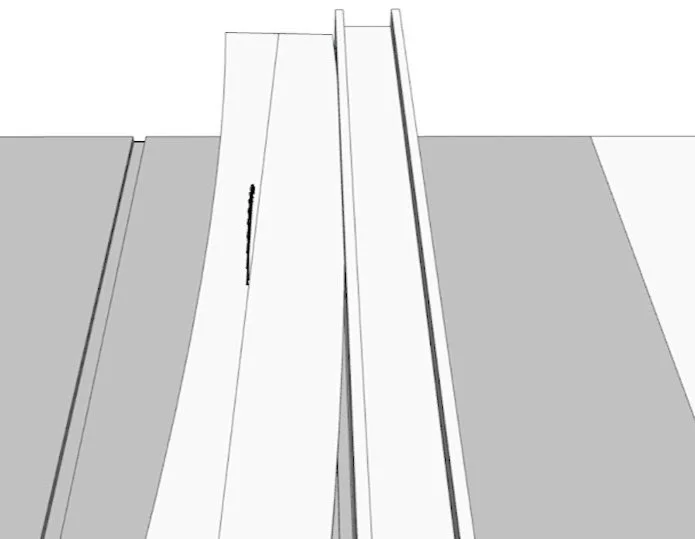

Crooked Edges

A board with a crook—or curved edge—brings another set of problems. Say you want to rip it down the middle. You might place the crowned edge against the fence. But with only one point of contact, the board won’t run straight.

This is little better than a freehand cut, and any shifting side to side creates dangerous pressure on the blade, increasing the risk of kickback.

If you use the hollow edge against the fence, the board must be twisted slightly to get two points of contact. But maintaining that alignment means the board wraps around the fence. As a result, the center line shifts relative to the blade—again, creating dangerous side pressure.

You must have a straight edge against the fence if you want to rip a board safely on the table saw.

Safe Alternatives

This is why we have jointers: to make one face flat to rest on the saw table, and one edge straight to ride along the fence.

But what if you don’t have a jointer?

A band saw makes an excellent ripping tool. I often use mine to rip rough boards that are too wide for my jointer. Even a smaller band saw with a narrow blade can follow a reasonably straight pencil line, creating an edge suitable for a cleaner table saw cut. A handheld jigsaw can work in a pinch, too.

That takes care of the edge—but what about the face?

If a wide board is only slightly cupped, ripping it in half may eliminate the problem and make it safer to run on the table saw. The same goes for slightly twisted or bowed boards. If your rough stock is wider or longer than your final workpieces, breaking it down into smaller sections can significantly reduce the danger when you do move to the table saw.

There are also homemade jigs to create a straight edge safely on the table saw, and router jigs to flatten a rough face. You might even use a hand plane to knock off high spots so you can maintain stability during a cut.

Final Thoughts on Safety

Don’t forget the value of a blade guard and splitter (or riving knife). If a board applies pressure to the blade’s side, you’ll be much safer with one of these in place. A splitter won’t eliminate all the risks of working with rough stock—but it does protect the back teeth of the blade, which are most likely to dig in, lift the board, and throw it back.

I’m not saying you can safely cut any rough board just because you have a splitter or riving knife in place. But it’s your best line of defense if you choose to work with slightly imperfect stock.

I hope this gives you the information you need to make smart, safe decisions in your shop.

Happy woodworking!

Need some cool tools for your shop? Browse my Amazon Shop for inspiration.

(This link is an affiliate link. If you make a purchase, I may receive a small commission.)