HOW TO GROUND YOUR DUST COLLECTION

Learn how to safely ground your PVC dust collection system to prevent static shocks in your woodworking shop, with step-by-step tips for ductwork, flex hoses, and blast gates.

Back in 2019, I made a video explaining why I believe it’s a myth that the dust inside the PVC ductwork of a non-industrial woodworking shop can be ignited by static electricity, causing a fire or explosion. I backed my opinion up with a paper written by an MIT scientist who is way smarter than all the folks arguing about it on the internet. If you're interested in that debate, I’ll link to that video below.

But the fact is, some people simply want to ground their PVC ductwork. And it’s not my job to force my opinions on you. My job is to make your shop time more enjoyable. And if grounding your ductwork makes your shop time more enjoyable, I think you should do it—especially if you occasionally get a little shock that may distract you while you're using a dangerous machine. That wouldn’t be good.

So in this article, I will teach you how to ground a PVC dust collection system properly, including answering some of the most common questions people have—such as how to address your flex hose, whether to run wire inside or outside the ductwork, and how to get that charge from the pipes and hoses into the physical ground.

The Concept

As air and sawdust flow through your hoses and ducts, it generates static electricity. That static charge can build up and give you a shock when you touch a pipe, a hose, or sometimes even a machine. A shock from PVC ductwork or a long flex hose isn’t likely to be painful, but it can be dangerous if it distracts you at the wrong time.

The reason PVC is unlikely to deliver much of a shock is because it is an insulator. That means very little of the static that builds up inside the duct will transfer through the walls of the pipe and into your body. That doesn’t mean there will be no charge on the outside of a PVC duct. You need only run your hand over the surface of the pipe after running dust through it for a few minutes to feel the charge on the outer surface.

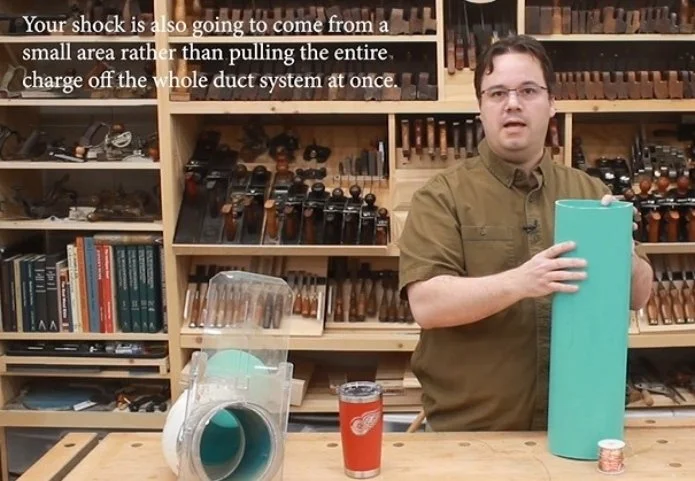

The idea, then, is to give that static charge a direct route to the ground so it won’t build up. This is done by running a wire through the whole system. It doesn’t have to be a heavy-duty wire. I use bare 18-gauge copper because it’s inexpensive yet durable enough to do the job. I’ll link to the wire I use below this article if you need some.

Wiring PVC Pipe

Among the many endless debates involving dust collection systems is whether you should run the grounding wire on the outside of the pipe or the inside.

As I said, PVC is an insulator. The bulk of the charge will be contained inside the pipe where it can’t reach you. But some of it clearly does migrate to the outside of the system. So we want to dissipate that interior charge as much as we can.

The problem is it’s difficult to run a wire inside a duct without creating all sorts of places for chips to get caught and eventually turn into obstructions. I did once read about a clever method to run strips of foil tape inside the ducts—but that’s very difficult to do inside a long length of pipe.

I use pilot holes and ¾ inch screws for grounding my dust collection pipes.

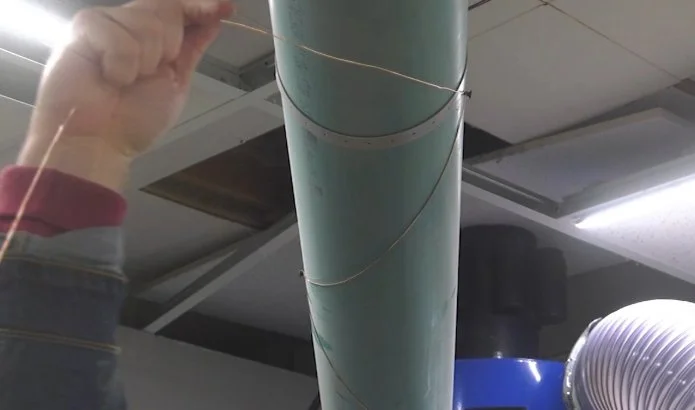

I prefer to bore pilot holes and drive ¾-inch screws into the pipe every foot or so, alternating from one side of the pipe to the other. Then I wrap my wire around each screw head down the length of the pipe. There’s no need to spiral the wire all the way around the pipe—just zig-zag from one side to the other.

I wrap my wire around each screw head down the length of the pipe and zig-zag from one side to the other.

If your wire isn’t long enough to run the entire length of the system, just start a new piece on the same screw head where the last piece ended.

As long as the screws only protrude into the interior of the pipe a small amount, they shouldn’t catch any debris. And as long as your pilot holes aren’t too large, the screws should plug any potential leaks. Each screw will act like a little lightning rod to capture the charge both inside and outside the pipe and channel it through the copper wire.

Grounding Flex Hose and Blast Gates

Flex hose is really easy to ground because it usually has an integrated wire. Simply expose the end and connect your copper wire to it.

Most flex hose has an integrated wire. Expose the wire and connect your copper wire to it.

If your flex hose doesn’t have an integrated wire, you’ll have to wrap the copper wire around the outside—and that’s going to be a pain because you’ll have to follow each rib. Otherwise, the wire may hang loose and get caught on something. Honestly, if you want to ground your system, you should switch to flex hose with an integrated wire.

All of my blast gates are acrylic, and there’s no need to connect them to the ground. But if you have metal blast gates, you should connect the grounding wire to them as well.

Finding the Ground

So now that you have a copper wire running from where the flex hose attaches to your machine all the way to your dust collector—how do you get it to ground?

You do not have to physically drive a stake into the earth and connect the wire to it. Your dust collector is already grounded through the AC outlet in the wall. Just connect the end of the wire to the metal body of the dust collector itself, and you’ll tie everything together.

Connecting the end of the copper wire with the metal body of your dust collector will tie everything together.

Another option is to connect the opposite end of the wire (that comes off your flex hose) to the body of the machine the hose is connected to—such as your table saw.

Now that your system is grounded, you can sleep better knowing you’re much less likely to get a shock from it. But don’t bother trying to argue with me about preventing an explosion—we’re running small woodworking shops, not flour mills.

Don’t forget to check out the links below for more information. Happy woodworking!

Can Woodworking Dust REALLY explode?

(The links below are affiliate links. If you make a purchase, I may receive a small commission.)

-Grounding wire: https://amzn.to/3uFxx78

Need some cool tools for your shop? Browse my Amazon Store for inspiration.