HOW TO STOP WOOD PANELS FROM WARPING

Do alternating growth rings really prevent table tops from warping? Learn why this common woodworking myth persists, how wood actually moves, and how proper joinery—not board orientation—is the real key to flat, stable panels.

If there’s one thing that’s popular in the woodworking world these days, it’s a good old-fashioned myth-busting video. Some of them are complete nonsense, of course. But this myth? It’s real—and I’d guess 90% or more of you have fallen for it. I once did myself, because almost every book or magazine I read early on as a woodworker told me the same thing: flat panels—such as table tops and cabinet tops—will warp uncontrollably if you don’t cut them into narrow pieces, flip every other board to alternate the grain direction, and then glue them back together.

This is a myth.

I don’t know when it started, but if you look at surviving furniture from 100 years ago or earlier, you’ll find some tops with alternating growth rings and others without. In both cases, some are warped, and some are not.

That’s because all wood warps under the right conditions. Alternating growth rings can’t stop that—it only changes how the warping shows up over time. The only truly effective way to manage warping is through proper joinery and ongoing care for the piece. Let me explain.

Wood Movement Is Inevitable

Wood is always swelling and shrinking as it tries to maintain equilibrium with the humidity in the air around it. Applying a finish helps slow these changes, but it doesn’t stop them.

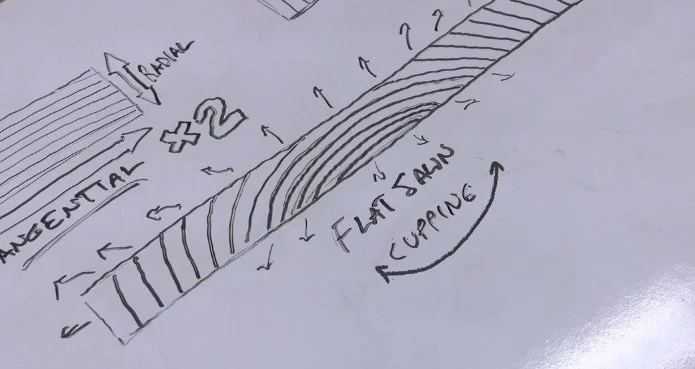

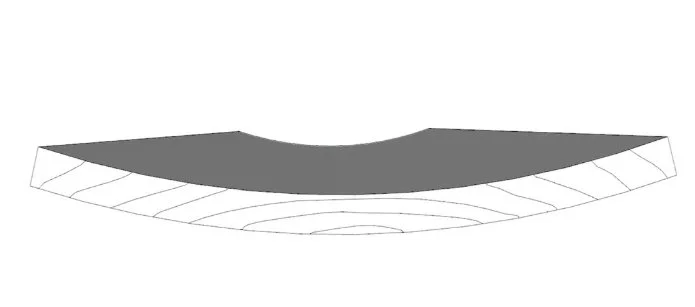

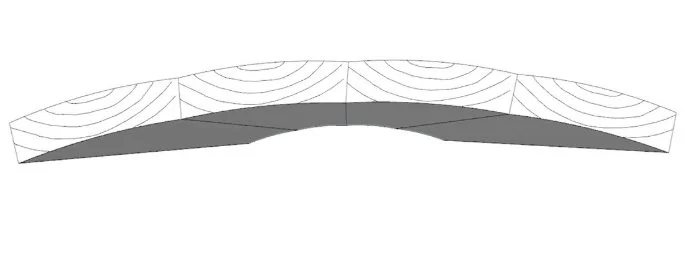

If one side of a board is significantly damper than the other, the board will cup toward the dry side. But what’s most common in furniture is for both sides of a board to absorb moisture evenly from the air. The result? A cupping away from the center of the tree—or opposite the curve of the growth rings.

When in a temperature controlled environment, both sides of a board absorb moisture evenly. As a result, the board will curve of the growth rings.

Over time, these cycles of summer swelling and winter shrinking cause the surface fibers on the cupped side to become permanently compressed, and the board never fully flattens again.

Why the Myth Persists

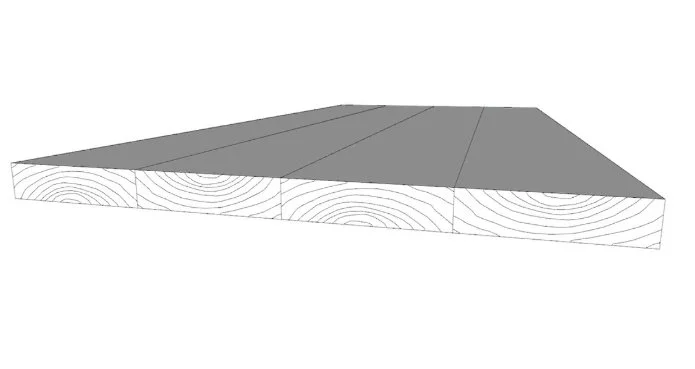

Because of this, many fear that if you build a table top from a solid slab of wood, you might eventually end up with a big potato-chip shape. So they cut the slab into strips—or use narrower boards to begin with—then alternate the direction of the growth rings and glue up their solid panel.

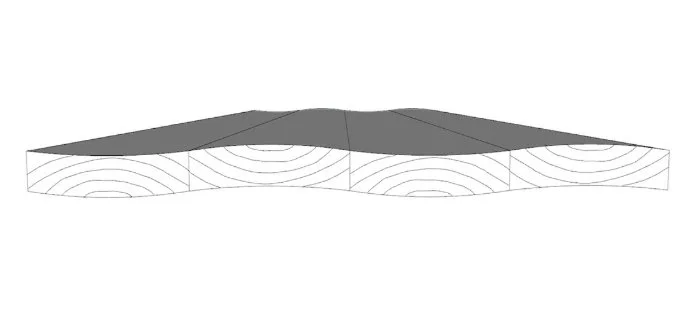

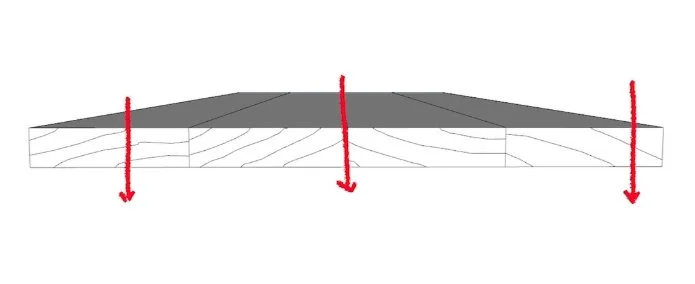

The idea is that, while each of these boards may cup, they’ll do so in alternating directions. Instead of a big potato chip, you might end up with a wavy washboard surface that—while exaggerated here—will be less noticeable overall.

Theoretically, that’s true. The worst-case scenario for a panel made from alternating strips is less dramatic than for a single, wide board. But the fallacy is that either of these worst-case scenarios are inevitable. They aren’t.

Joinery Is What Really Matters

You can actually stop a panel from warping—not by how you orient the growth rings, but by how you construct the project itself.

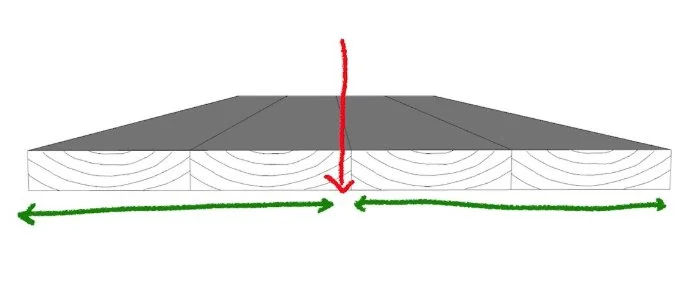

Consider a cabinet top made from a single slab, or from narrow boards with the growth rings all facing in the same direction. If it cups, you know exactly how it will curve: opposite the direction of the growth rings. You can use that predictability to your advantage. For example, orient the board so the rings curve upward—this way, any cupping will be downward, pressing the edges tighter against the frame, with only the center of the panel rising slightly.

Now it will only take an anchor point at the center of each end to hold the panel flat. By anchoring it in the center, the rest of the panel can still grow wider or shrink narrower as the wood continues to move naturally.

Incidentally, the closer you get to the center of a tree, the less sapwood you’re likely to see. So, boards in this orientation—with the growth rings curving upward toward the show face—will usually look better in the finished project.

The Downside of Alternating Growth Rings

The real downside of alternating growth rings is that you lose control of the panel’s final appearance. But if you use joinery to prevent warping, you’re free to choose the most attractive side of each board in the panel.

If the best-looking panel results in a mix of ring directions, you do lose some predictability when it comes to potential warpage. In that case, you may need multiple anchor points to keep the panel flat.

For that, you’d use fasteners like figure-8s or slot-and-button joinery—methods that allow the panel to expand and contract in width without pulling up off the frame.

What About Large Table Tops?

What if you’re working on a large table top that can’t be fully secured to a sturdy frame? That’s what breadboard ends are for. These attach to the ends of panels in a way that keeps them flat while still allowing for expansion and contraction across the grain.

Final Thoughts

The point is, proper joinery is the key to preventing warping. If you build your project correctly, you don’t need to alternate the growth rings on your table tops. Instead, you can concentrate on arranging the boards in the most attractive way—free from the fear of a future potato chip.

Need some cool tools for your shop? Browse my Amazon Shop for inspiration.

(This link is an affiliate link. If you make a purchase, I may receive a small commission.)