USING LARGE ROUTER BITS SAFELY

That giant panel-raising router bit isn’t just intimidating—it’s a perfect example of how size, weight, and speed combine to make some bits far more dangerous than most woodworkers realize. Learn why heavy or oversized router bits demand slower RPMs, lighter passes, and router-table use to keep your fingers—and your shop—safe.

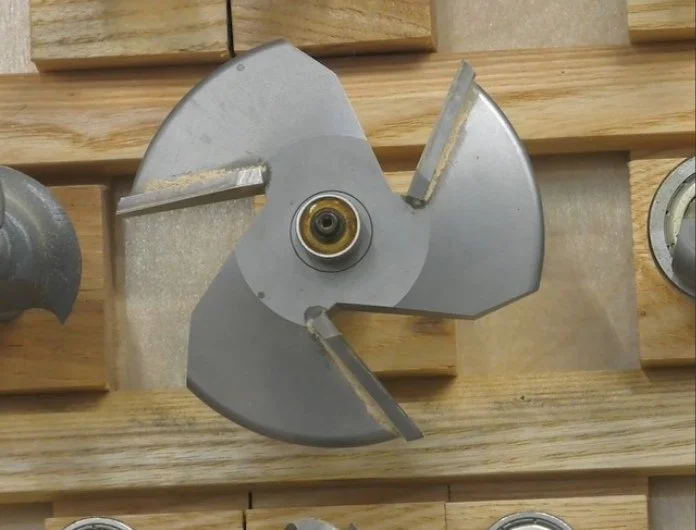

This is not a boat propeller or the Super Bas-O-Matic 76. It’s the scariest router bit I have ever used.

Don’t get me wrong—I’m not afraid of tools. I’ve used routers for many years, and while I recognize them as among the most dangerous tools in the average woodworking shop, I have never seen a bigger finger-eater than this.

Why is it so dangerous?

Is it because it’s designed to spin at well over a hundred miles an hour, completely unprotected by any sort of guard? Partly. But there’s more to it than that—something many woodworkers never think about. And it’s something that doesn’t just apply to this bit. It can make other bits you already own incredibly dangerous as well.

So this isn’t just about this router bit. It’s also about the bits you use every day—and how you might be putting your fingers at serious risk without even realizing it.

The next couple of minutes might make you a better woodworker.

What Is The Giant Bit For?

The monster is a panel-raising bit, designed to cut bevels on large panels like ones we made for a chest of drawers. Similar bits are commonly used to make kitchen cabinet doors, so a lot of woodworkers—even hobbyists—will use something like this at some point.

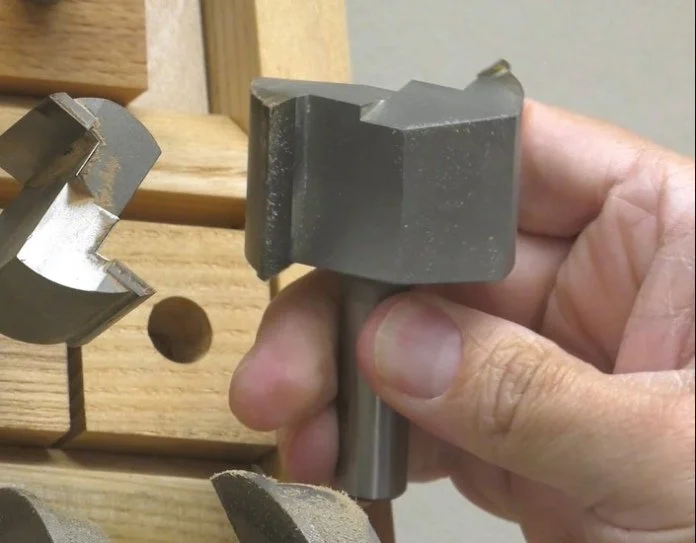

This particular bit is 3-1/2 inches in diameter and weighs nearly 3/4 of a pound.

Large bits like this should never be used in a handheld router.

Even if your router motor is powerful enough to spin cutters this size, the weight makes the tool harder to control—and the consequences of losing control are far too high. This is a router-table-only bit, and I believe other extra-large bits should also be reserved for router table use.

Where Do You Draw the Line?

That’s the tricky part.

Looking at my bit rack (and yes, I have more bits than most), you’ll see plenty of straight bits and edge profile bits under an inch in diameter. These are generally safe for handheld routing.

Then you get into larger profile bits used for tabletops. They’re not as big as a panel raiser, but they’re often around 2-1/2 inches in diameter. Most people agree that’s about the maximum size for handheld use—and I agree.

Anything over 2-1/2 inches belongs on a router table.

But here’s the catch: just because a bit is smaller than that doesn’t automatically make it safe.

Weight Matters More Than You Think

Take this 2-inch straight bit, for example. It’s smaller in diameter than those edge profile bits, but it weighs more than twice as much.

Despite its size, I consider a bit like this sketchy at best because of its mass. People rarely think about that, and it can really get you into trouble.

Heavy bits—like large straight bits, box cores, roundovers, or bullnose bits—are often too heavy for handheld use. And they can even be unsafe in a router table if you don’t take proper precautions.

Some routers, especially lower-quality ones, aren’t perfectly balanced. There can be a tiny amount of spindle runout. You may not notice it, but when you spin a heavy bit, those micro-vibrations can cause the collet to loosen.

That actually happened to me years ago.

Thankfully, the bit was in a router table, so it just slipped downward. If it had been in a handheld router, it could have become a deadly projectile.

Because of this, while I usually tell people not to overtighten router bits, I do apply a little extra torque when using large or heavy bits.

Size, Speed, and Why RPM Matters

Weight isn’t the only issue. Size also matters—especially when combined with speed.

The larger the bit, the slower it should spin.

Let’s compare two bit sizes, such as the ones in the above example: one is 3-1/2 inches in diameter, the other is 1-1/2 inches. What really matters is the circumference—the distance the cutters travel in one revolution.

Large bit: about 11 inches per revolution

Small bit: about 4 inches per revolution

Many woodworkers run their tools at full speed all the time, so let’s say both bits are spinning at 22,000 RPM.

That means:

The small bit’s cutters are moving around 125 MPH

The large bit’s cutters are screaming along at nearly 230 MPH

Same router setting. Over 100 MPH difference.

Router bits aren’t designed to move that fast or withstand that much centrifugal force. Excessive speed creates heat and increases the risk of cutter failure or the bit coming loose.

Slow that large bit down to around 12,000 RPM, and now both bits are cutting at roughly the same surface speed—about 125 MPH.

Two different bits. Two very different RPMs. Same effective cutting speed.

That concept trips up a lot of people. You can learn more about it here.

Setting Router Speed Without RPM Numbers

If your router has a numbered dial instead of actual RPM markings, start by checking your manual or looking up your model online.

For example, one of my routers ranges from 9,000 to 22,000 RPM. That tells me:

Dial 1 ≈ 9K

Dial max ≈ 22K

From there, I can estimate the settings in between and write them down for future reference.

Most variable-speed routers run roughly from 8–9K on the low end to 22–24K on the high end. If you can’t find exact specs, use that as a guideline.

Then test cautiously. Increase speed slowly. If you feel any vibration, back it off and note that maximum safe speed for that bit.

Don’t Take Aggressive Cuts

Another important factor is cut depth.

With a powerful router you can take deep cuts—but that doesn’t mean you should.

If a big bit catches a knot during an aggressive pass, it can rip the workpiece right out of your hands. That’s why push paddles are an absolute must with large bits. You always want something between your hands and the cutter.

Cut quality also matters. Even if a full-depth pass is possible, you’ll stress both your router and your bit, and you’re far more likely to get chatter marks, scorching, or tearout.

You’ll get much cleaner results by shaping large profiles in two or three passes, finishing with a very light final cut.

Respect the Tool

This big helicopter-looking bit still tightens my pucker. But there’s no need to fear your tools. Just learn how they work. Understand their limitations. Follow basic safety guidelines. I hope this helps.

This post may contain affiliate links. If you make a purchase, we may receive a small commission.

Need some cool tools for your shop? Browse my Amazon Storefront for inspiration.