HOW TO MAKE CAULK & ADHESIVE LAST FOREVER

Stop wasting half-used tubes of caulk! These two airtight sealing tricks—a glove finger sleeve and a hot glue cap—keep your caulk or adhesive fresh for months, ready for the next job.

This article is brief, but it should solve a big problem for a lot of you—specifically, how to stop wasting caulk when you’ve only used part of a tube. The question is: How do you keep what remains fresh?

I’ve seen a ton of so-called “tips” claiming to solve this problem—wrapping the nozzle with tape, sticking a screw in the end, twisting on a wire nut, and so on. Most of those ideas don’t really work long-term because they don’t fully seal the tube, and that’s the key. You have to keep all the air out—not just most of it. The better you seal the tube, the longer it will last after it’s opened.

Over time, I’ve found two methods that work really well.

The first is ideal for flexible sealants like silicone or latex caulk.

The second works better for adhesives that harden, such as Liquid Nails or other construction adhesives.

Method 1: The Glove Finger Trick

Most of the time, when I’m working with caulk, I wear gloves to keep it off my hands. When I’m finished, I simply cut a finger off one of the gloves and slip it over the nozzle.

Now, this won’t fit tightly on its own, so there’s one more step. Hold the glove finger in place as you squeeze a little caulk out—you should feel it squishing around the outside of the nozzle.

That bit of pressure helps hold the sleeve in place. Over time, the silicone or latex will begin to cure, but instead of curing from the tip of the nozzle inward, it will cure from the opening of the glove sleeve outward, creating an airtight seal.

This method works best with flexible caulks like silicone or latex. You can use it with hardening adhesives, but I’ve found they don’t last quite as long that way.

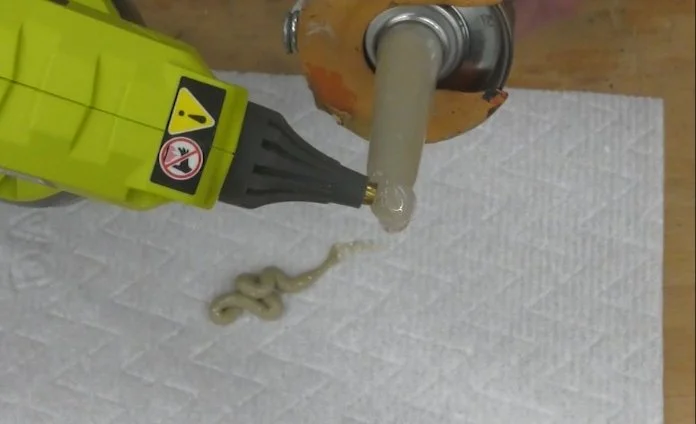

Method 2: The Hot Glue Seal

For adhesives that harden—like construction adhesives—I prefer a different approach.

Grab your hot melt glue gun (one of the most useful tools around the shop, by the way). Simply apply a generous blob of hot glue over the end of the tube nozzle, covering it completely. Once it cools, you can even add another layer just to be sure you have a solid, airtight seal.

When you’re ready to use the tube again, even months later, the glue cap peels off cleanly—and the adhesive inside will still be fresh.

Conclusion

Both of these methods can save you a lot of money and waste over time. Try them out and see which works best for you.

Happy woodworking!

This post may contain affiliate links. If you make a purchase, we may receive a small commission.

Need some cool tools for your shop? Browse my Amazon Storefront for inspiration.