THE ONLY 3 BANDSAW BLADES YOU NEED

Choosing the right bandsaw blade doesn’t have to be confusing—just focus on width, steel type, and tooth geometry to get clean, accurate cuts every time. This guide breaks down exactly what to buy so you can spend less time guessing and more time building.

When was the last time you had to buy a bandsaw blade? It was confusing, wasn’t it? Different types of metal, varying tooth counts, and geometry—these are not meaningless choices. Choosing the right blade can make a big difference in how your next project turns out!

Years ago, I made a comprehensive tutorial on this subject. But today, I want to simplify it for those of you who just need to know what to buy so you can get back to work. So here's the shortened version:

Blade Width

Let’s start with the blade width. Generally, you want to use the widest blade you can for the cut you are making because a wider blade works like the rudder on a ship, guiding your cut and keeping it on course. For example, you can cut a gradual curve with a 3/16” blade, but it’s likely to be smoother if cut with a wider one. The extra width helps prevent overcorrection as you steer.

The picture above is a guide to choosing the right blade width for the cuts you most often make. This is, of course, not to scale, but it shows the minimum radius each blade width can cut. Of course, you don't need a different blade for each radius. I’ll recommend a couple of general-purpose widths in this article.

Types of Steel

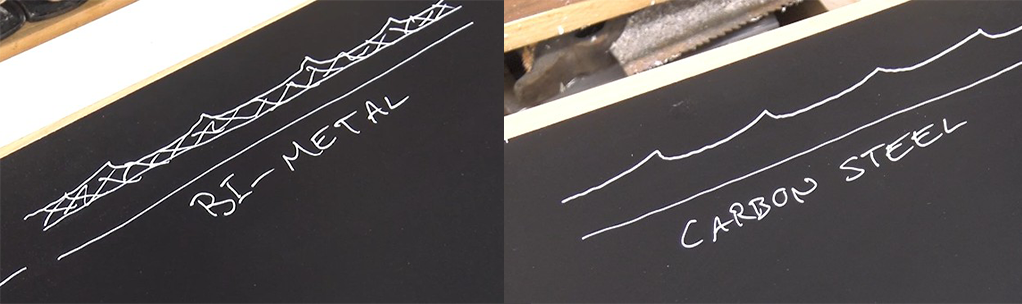

Now, let’s address one of the the two most confusing aspects when it comes to choosing bandsaw blades—the types of steel.

You’re likely to find carbon steel and bi-metal bandsaw blades. Bi-metal blades are more expensive because the toothed edge is made from a harder, more durable steel. These are most commonly used for cutting metal, while carbon steel blades are more economical and better suited for woodworking.

Bi-metal blades are most commonly used for metal, while carbon steel is more economical and better suited for woodworking.

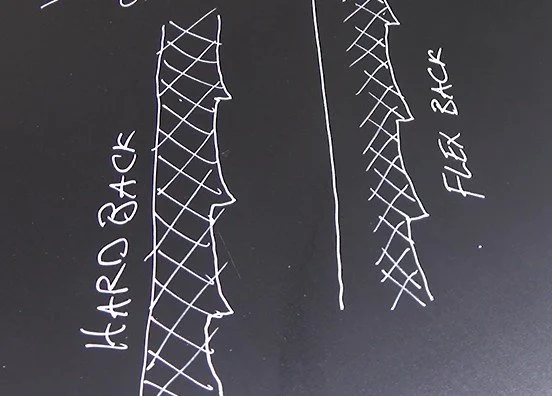

You will also find hard-back and flex-back blades. Hard-back blades are heat-treated all the way through the steel, making them stiffer. As a result, they tend to drift less when cutting straight lines, such as when ripping, resawing, or cutting joinery on the bandsaw. Flex-back blades, on the other hand, are heat-treated only along the teeth, leaving the backs more flexible to better absorb the stress of cutting curves. In most cases, I recommend flex-back blades because they are more versatile and seem to break less.

Hard-back vs Flex-back blades

Teeth: Number and Geometry

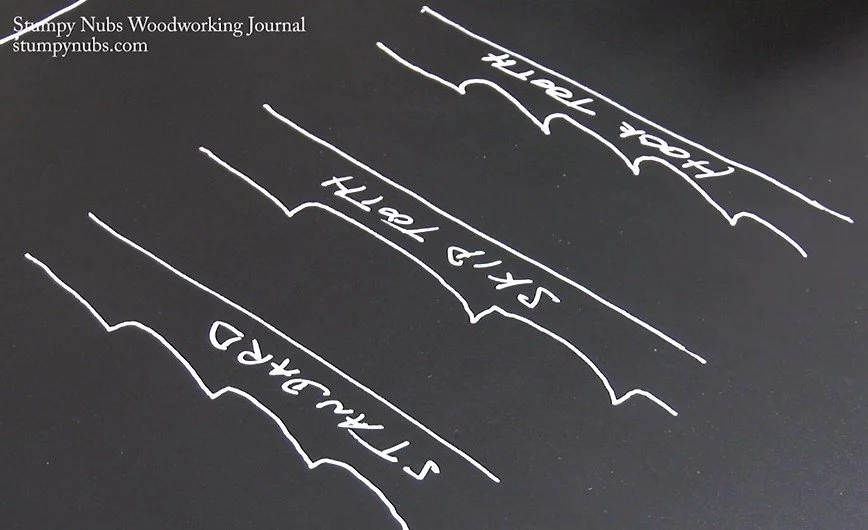

The other most confusing aspect of band saw blades is the teeth. Here we need to consider both the number of teeth per inch and their geometry.

The fewer teeth on a blade, the wider the gullets are likely to be. Wider gullets clear sawdust from the kerf more efficiently, so the blade will cut faster without scorching the wood or drifting within the cut. But more teeth usually leave a smoother surface behind. So, you have to find a balance.

That brings us to tooth geometry. The most common types are standard, hook, and skip-tooth.

Standard Teeth are evenly spaced for general-purpose cuts.

Skip-Tooth Blades are missing every other tooth, leaving wider gullets between them than would otherwise be possible on narrow blades, where the gullets can only be so deep. These are great for cutting tight curves in thicker materials or for finish-quality resaw cuts.

Hook-Tooth Blades are very aggressive and are most often used for fast rips and other coarse cuts, or to cut thick stock where fast cutting is important to prevent overheating.

My Blade Recommendations

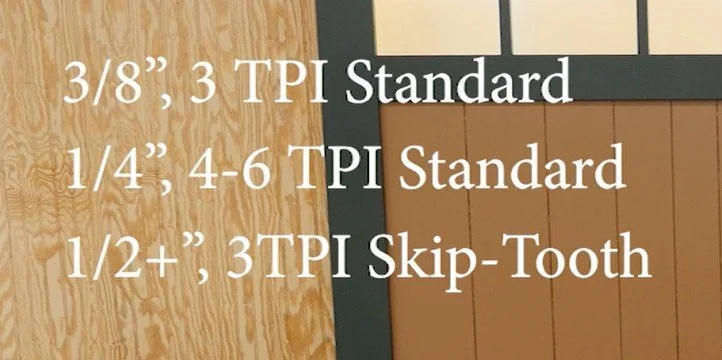

Now, let’s distill all that information into the actual blades I recommend you have in your shop.

If you mostly work with 3/4” thick boards, a 3/8” wide, flex-back blade with 3 standard teeth per inch would be a great choice. It’s just narrow enough for the most common curves you’re likely to cut, and it’s just wide enough to cut straight lines and even do a little resawing.

I also like to have a 1/4” flex-back blade with 4 to 6 teeth per inch. The finer teeth give me a smoother cut on stock thinner than 3/4”, and I can cut tighter curves when needed.

If you cut a lot of bandsaw joinery or resaw boards wider than three or four inches, you may want a 1/2-inch or wider, 3 TPI blade. I like the skip-tooth geometry for that.

Of course, there are other blades for other situations, but these will cover almost all of your needs.

Blade Brands

As for the brand, you get what you pay for. I recommend avoiding the cheapest ones, which may drift more and break more frequently. I’ve had a lot of success with Sterling blades, but there are other decent choices out there.

Need some cool tools for your shop? Browse my Amazon Shop for inspiration.

(This link is an affiliate link. If you make a purchase, I may receive a small commission.)