CHOOSING THE RIGHT CBN WHEEL GRITS

Choosing the right CBN grinding wheel grit depends on what you sharpen most—turning tools, woodworking tools, or both—not on traditional grit rules. This guide breaks down the best grit and wheel combinations to maximize edge quality, tool life, and value for your shop.

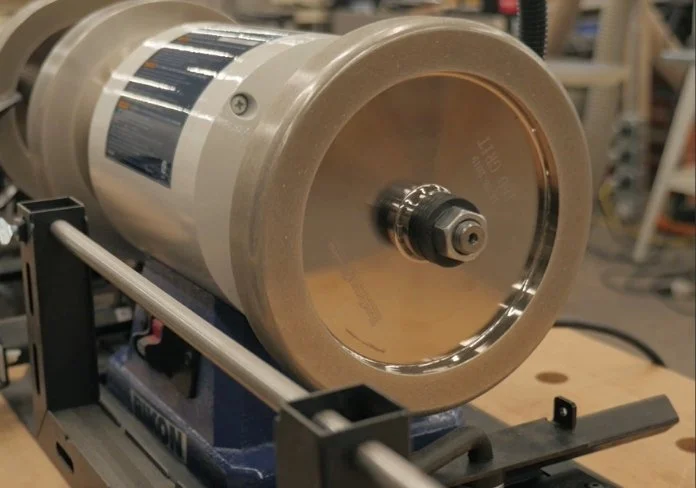

A number of years ago, we made a comprehensive tutorial about CBN grinding wheels and how they’ve changed everything for woodturners and woodworkers. They work quickly, don’t require dressing, don’t overheat tools like traditional grinding wheels, and they don’t wear down and get smaller over time. That last point is important, because it allows you to set tool rests and sharpening jigs more precisely, remove less steel, and make your tools last much longer.

If you’ve never heard of CBN wheels, I recommend watching that earlier 10-minute video. It answers most of the common questions people have about them.

Today, I want to focus on the number-one question I get about CBN wheels:

Which grit should I get?

I touched on this in the longer video, but here I want to be more specific—because the answer depends on what you sharpen most and what your budget looks like. Also, keep this in mind as we go: grit numbers are not universal. CBN wheels cut very differently than traditional grinding wheels of the same grit. So forget everything you think you know about grinder grits, and let’s start fresh.

We’ll begin with woodturners, then move on to woodworkers, and finally talk about grinders themselves.

CBN Grit Recommendations for Woodturners

If you’re a woodturner and you can only afford one CBN wheel right now, get 180 grit.

It’s coarse enough to reshape a bevel or grind a new tool profile reasonably quickly, but it still leaves a very usable turning edge right off the grinder—especially for gouges and other tools meant to cut aggressively. A 180-grit wheel is also excellent for raising burrs on scrapers for cleaning up bowl bottoms.

The Most Versatile Turning Wheel

If I wanted just one highly versatile wheel for turning, I’d choose a 4-in-1 wheel in 180 grit.

This profile was designed to make grinding a variety of otherwise tricky tools much easier:

The radiused edge helps grind round-nosed scrapers consistently, without the uneven results that can come from swinging the handle in a wide arc.

That same radius is useful for hollowing tools and other odd-shaped cutters.

There’s about an inch of flat side surface for those who prefer not to hollow-grind skews and scrapers.

A 90-degree shoulder on the inside edge allows for relief cuts on hook-style scrapers.

These features are unique to the 4-in-1 design, and if I could only own one CBN wheel for woodturning, this would be it.

Adding a Second Wheel for Turning

If your budget allows for a second wheel on the other side of the grinder, I’d add a 600-grit wheel.

This grit is ideal for tools you want extremely sharp right off the grinder, such as skews, or for gouges you want to stay sharp longer. A finer edge fractures less and holds up better, which means fewer trips back to the grinder and less steel removed over time.

For this finer wheel, I would not choose the 4-in-1 design. Instead, I’d go with a Mega-Square wheel.

The Mega-Square wheel has a wide 1½-inch grinding surface, which gives you plenty of room for gouges with swept-back wings, like an Irish grind. It also provides a broad side surface for flat-ground skews and scrapers.

A 180-grit 4-in-1 wheel paired with a 600-grit Mega-Square wheel offers outstanding versatility for woodturning.

CBN Grit Recommendations for Woodworkers

If you’re primarily a woodworker, your needs are a bit different. The key is understanding the difference between grinding and sharpening.

A woodturner goes straight from the grinder to the wood—grinding is sharpening. A woodworker, on the other hand, typically uses the grinder only for heavy work: changing bevel angles, repairing chips, or reshaping tools. Stones and strops handle the final sharpening and polishing.

One Wheel for Woodworkers

If you can only afford one CBN wheel as a woodworker, go with 80 grit.

This is very different from an 80-grit traditional wheel. CBN cuts faster and leaves a finer surface. An 80-grit CBN wheel removes steel quickly but still leaves an edge that can be refined with stones without taking all day.

For example, you might go from:

80-grit CBN

to a double-sided diamond stone (300 grit, then 1000 grit)

and finally to a strop and compound

Adding a Second Wheel for Woodworking

If you can add a second wheel, choose 350 grit.

This can replace the coarse side of your diamond stone and save a lot of time. A typical progression might look like this:

Rough shaping or repair on 80-grit CBN

Refinement on 350-grit CBN

Final sharpening on a 1000-grit stone

Polishing on a strop

For woodworkers, the Mega-Square wheels make the most sense for both grits. The 4-in-1 design doesn’t offer much benefit if you’re not grinding turning tools.

If You’re Both a Woodworker and a Woodturner

If you do some of both but don’t want to invest in multiple grinders and wheel sets, here’s a practical compromise:

An 80-grit 4-in-1 wheel for rough shaping of both turning and woodworking tools

A 350-grit Mega-Square wheel for refining edges

This setup involves some compromises, but it delivers the widest versatility for the least investment.

Grinder Recommendations

I strongly recommend a slow-speed grinder, around 1750 RPM. That said, if you already own a 3500 RPM grinder, CBN wheels are still much safer than traditional wheels because they keep tools far cooler.

Be cautious with finer grits on high-speed grinders, though—they can generate more heat than coarser wheels.

Motor Size: ½ HP vs. 1 HP

Either will work.

You’re not hogging off steel like you would with a lawnmower blade, so it’s hard to bog down even a half-horsepower grinder. The real difference is startup time. CBN wheels can weigh up to five pounds each:

A ½ HP grinder may take around 8 seconds to reach full speed

A 1 HP grinder may take only 2 seconds

If you’re a turner who frequently walks over for quick touch-ups, that startup time can matter. Otherwise, it’s mostly a matter of convenience.

This post may contain affiliate links. If you make a purchase, we may receive a small commission.

Need some cool tools for your shop? Browse my Amazon Storefront for inspiration.